Kinzanji-miso, very popular item among locals, can be purchased by weight in addition to various Wakayama’s souvenirs including locally produced side dishes and the sweet drink made from fermented rice.

Various gift-wrapped items can be purchased. Domestic shipping is available.

There is a wide variety of goods in Hishiokan including the world’s Michelin- chef recognized pure black bean soy sauce in addition to various Yuasa’s soy products including the Rosanjin soy sauce, Curry soy sauce, and Kinzanji miso, which is Yuasa’s local specialty. Sampling is available, so please feel free to try our various products that are specially offered at Hishiokan.

The soy sauce produced at Kuyogura goes through pasteurization, then bottled for shipment. Using a special pasteurization equipment, we ensure to deliver safe and high-quality soy sauce to our customers.

Experience <300yen>

With discount coupon (100yen) and soft-serve ice cream (300yen).

This is a top view of the cedar barrels that were observed on the first floor.

To begin soy sauce brewing, first, make Koji (rice malt) by blending equal amount of steamed soybeans and toasted wheat, then add seed malt. Second, the Koji is placed in a tank with brine to create Moromi, and it is rested for approximately 1 to 2 years with repeated stirring.

Typically, soybeans are steamed; however, the traditional method is characterized by cooking soybeans slowly and using brine to ferment. By using this method, nutrients of soybeans including Isoflavone, Lecithin, and Saponin are fully extracted. The preparation of the soy sauce typically starts in winter and follows several steps as follows: letting the mixture mature in the natural cedar barrels for over a year, squeezing Moromi, transferring the raw soy sauce to large wooden vats, and precipitating impurities out of raw soy sauce. At the end, the liquid emerges on the top layer becomes soy sauce.

Kishu Yuasa is a birthplace of soy sauce. It has been said that the roots of soy sauce go back to Kamakura era (approximately in 1254). Hottoenmyokushi, the founder of Kokokuji ZenTemple located at Kishu Yura brought back the manufacturing method of Kinzanji miso (Kaizanji miso) from Kaizanji Temple in an ancient China.

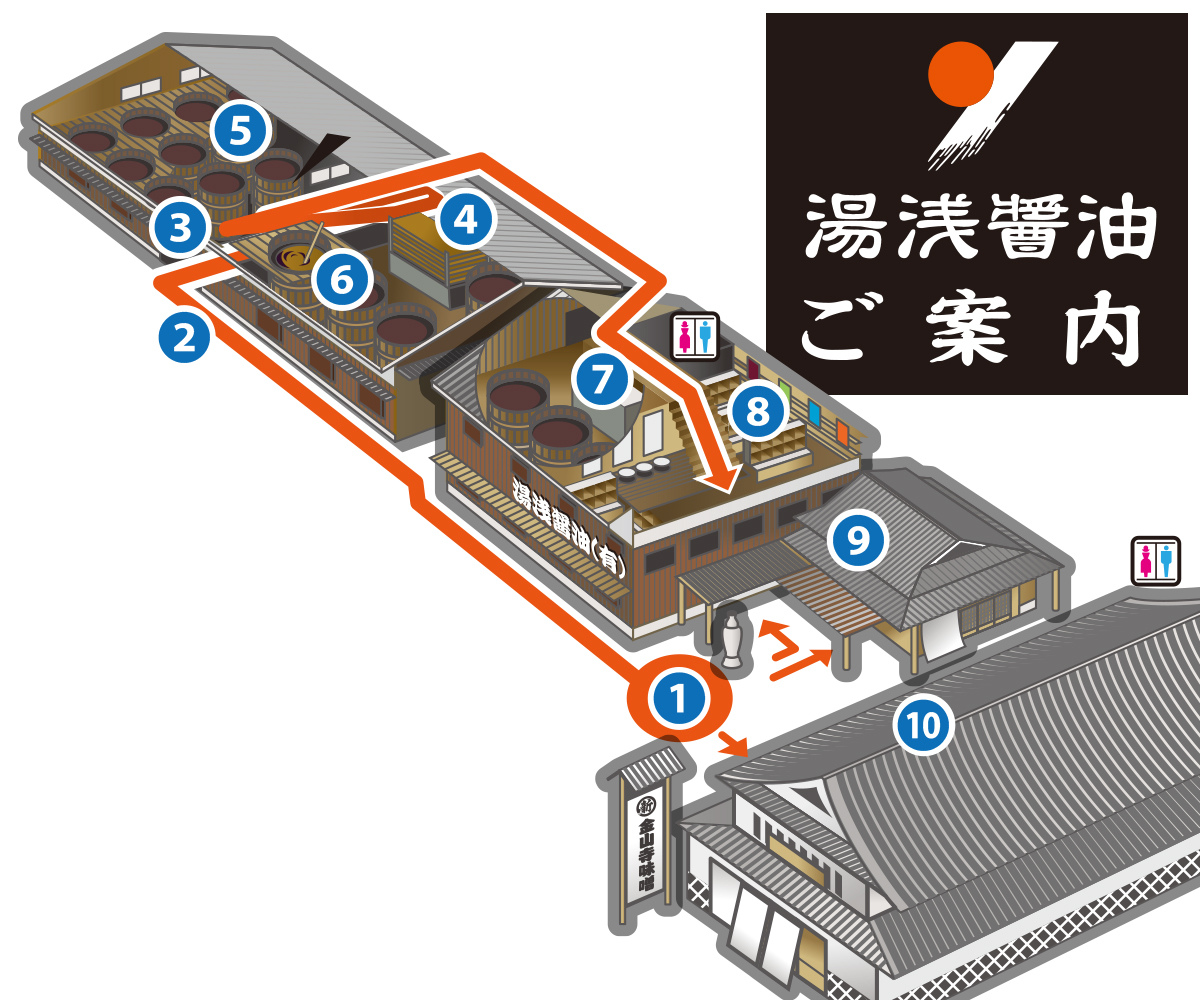

Kuyogura’s soy sauce storehouse tour enters from the side of the building on the first floor. Please wait to enter the storehouse if there is a group tour. The restroom is located at Hishiokan (8).

Kuyogura is a soy sauce storehouse owned byYuasa Soy Sauce Ltd. You are able to see the whole process of soy sauce production here.

When you proceed along routs indicated by numbers, you can see the history of soy sauce, Japanese cedar barrels, compression and filling equipment, oar insertion experience (extra fee) as well as the tasting and sampling.

Eleven Japanese cedar wood barrels are placed in Kuyogura, and each barrel is still filled up with Kuyogura’s original soy sauce.

Yuasa Soy Sauce Ltd. produces all of our soy sauce independently. Due to the use of “no water adding”method, our soy sauce maintains high purity and natural flavor of soy sauce.

Attention

At our storehouse, we pay full attention to safety of visitors; however, we appreciate your consideration where our staffs are working.

There are stairs in our storehouse, and the route goes from the order of 1st floor to the 2nd floor, and back to the 1st floor. Please ask the nearest staff if you need assistance with mobility. You can also enjoy shopping at Hishiokan (8) or rest at café Hishio(9).

The restroom is located at Hishiokan (8). Make sure to use a restroom prior to the soy sauce storehouse tour.